PosWeTool project indirectly financed by the European Union through the Horizont 2020 research and innovation program (Grant Agreement no. 873087)

.

SMASP has been selected for the development of the PosWeTool project within the SHOP4CF call for proposals.

The aim of SHOP4CF

The new era on human centered robotics in Europe with user friendly, plug and play solutions

SHOP4CF page

The problem

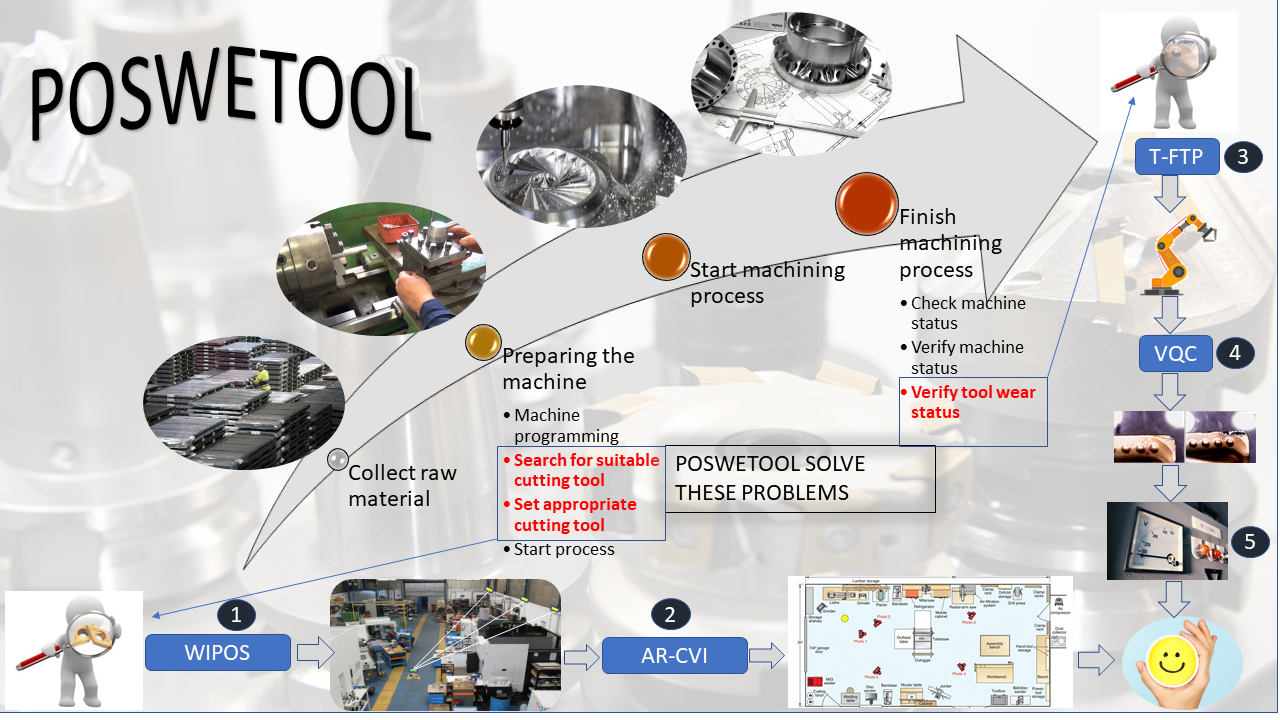

In machine shops, a large number of cutting tools are continuously used on a daily basis. Workers are preoccupied with production and pay less attention to putting the tools in the right place. Some of these tools are new, others are reusable or may be completely worn out.

The manufacturing workshop needs to have a clear indication of the quality of the tool wear, to decide whether to reuse or stop using it, as it depends on the quality of the manufactured part and to plan a stock of spare tooling to be able to continue manufacturing.

In order to solve these problems, the PosWeTool project was created.

The project PosWeTool

The main function is to identify the position of the cutting tools in the machine shop in the workspace and to show the status of each cutting tool, whether it is new or used; with its level of wear, on the other hand.

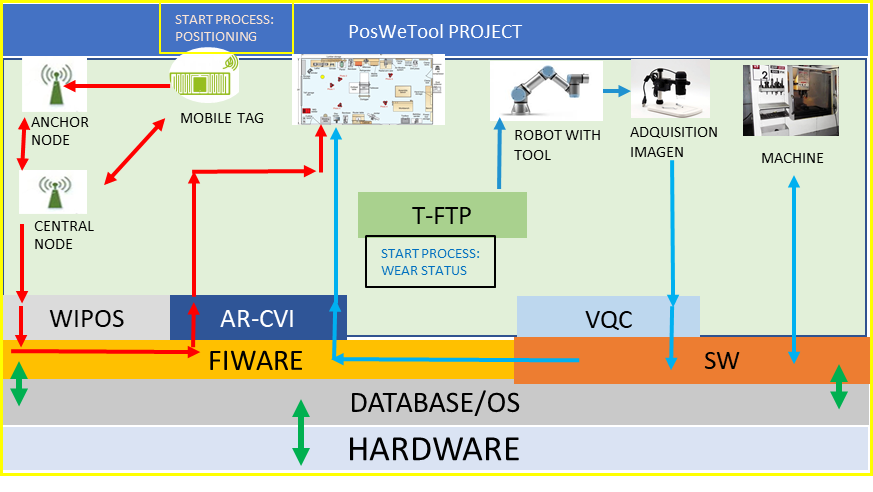

For the development of PosWeTool, different technologies will be applied, depending on the objective to be achieved.

To determine the positioning of the tool, UWB technology will be implemented and, on the other hand, to know the state of the tool, with its level of gradual wear, especially for used tools, image recognition technology will be placed, by means of a digital camera, in a Cobot to carry out a 360º visual inspection of the cutting tool in order to carry out a visual inspection and measurements of tool wear.

In addition, the energy consumption of the machine will be extracted and associated with the state of deterioration of the cutting tool. The PosWeTool project consists of two main functional blocks:

- Intelligent software development: includes the cutting tool database, artificial intelligence algorithms, middelware and GUI to interact with the user, transmit information and make the system intelligent.

- Technological evolution: will comprise two approaches:

- Tool positioning: it will be realised by integrating the SHOP4CF components; WI-POS to perform the positioning and AR-CVI to show it through a project the positioning of the tool on the factory layout.

- Tool wear and tear: this will be carried out using the components; VQC, which will compare images of a new tool with the current one, and AR-CVI which will show the results.

| The POSWETOOL project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 873087. Neither the European Commission (EC) nor any person acting on behalf of the Commission is responsible for how the following information is used. The views expressed in this publication are the sole responsibility of the authors and do not necessarily reflect the views of the EC. |  |

|---|